Another individual implementation and once again – a satisfied customer.

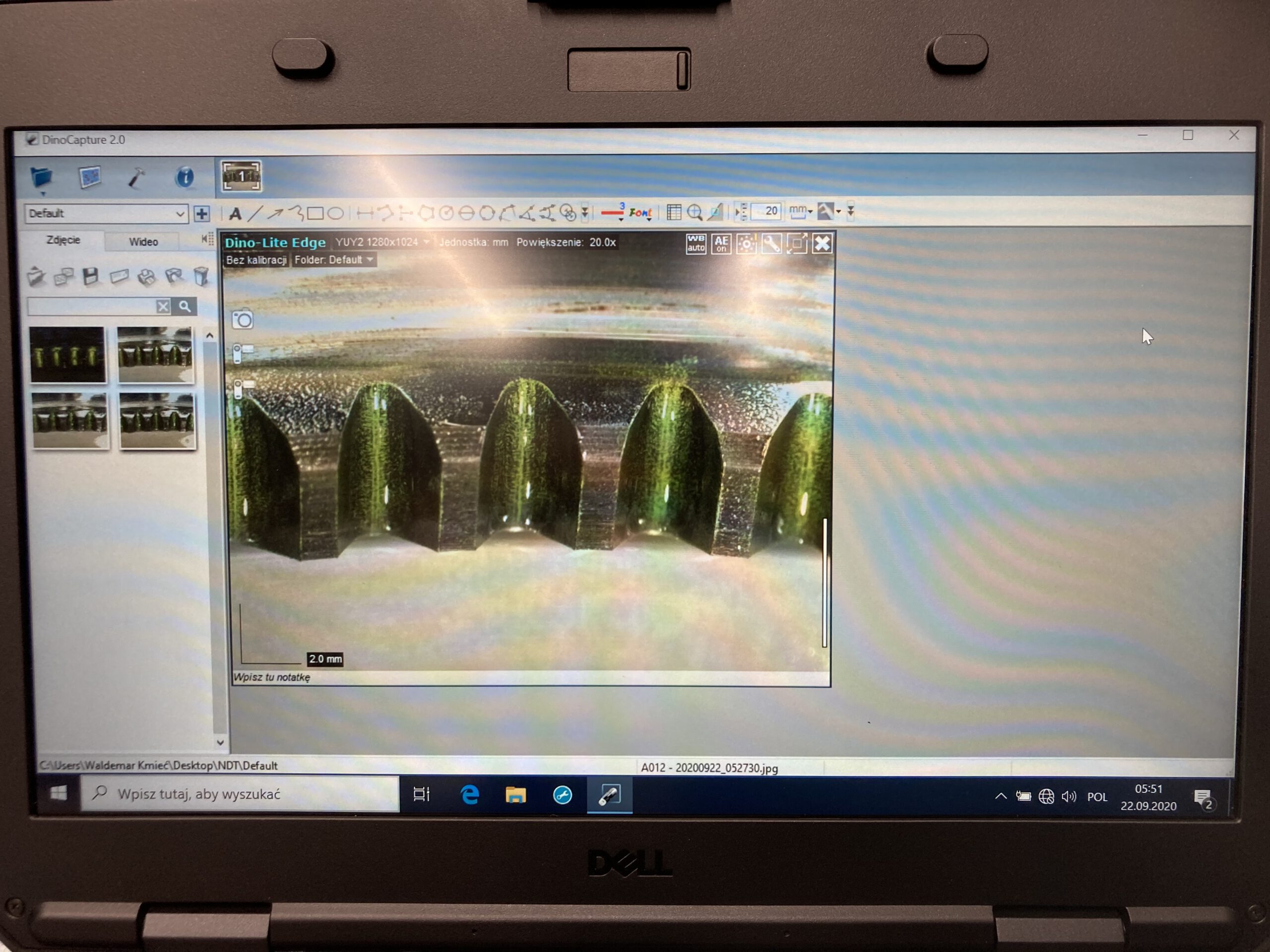

After the machining process, microcracks sometimes appeared in the gear notch.

During the operation, the microcracks progressed and in a short time they significantly enlarged, which threatened the durability of the entire system! Defective elements should be caught already at the production stage, so we have implemented a digital microscope under UV light for the QC (Quality Control) process in the MPI (Magnetic Particle Inspection) control. The microscope had to be small and mobile enough to literally fit into any notch. Microcracks are visible only at magnification from 20x, the optimal image was obtained at 60x magnification. Feel free to contact us regarding individual problems related to visual inspection.

We will try to solve the problem, adjust and implement the appropriate solution