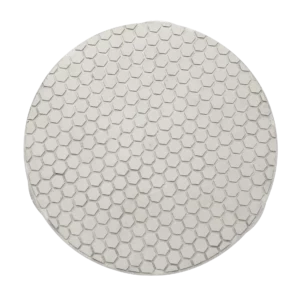

POS&POH sanding and polishing disc

- Compared to traditional silicon carbide sandpaper, POS/POH sanding discs are characterized by higher sanding efficiency and allow you to avoid time loss caused by frequent sandpaper changes.

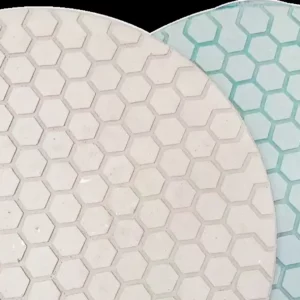

- Lower elasticity resulting in higher sample flatness compared to conventional silicon carbide sandpaper.

- High quality and reliable reproduction of experimental results.

- POS/POH grinding wheels can reduce the number of grinding steps, save grinding time and reduce the consumption of consumables, which is in line with the concept of low carbon dioxide emission and green environmental protection.

Product description

POH and POS abrasive discs are an effective alternative to metallographic sandpaper for precision grinding. After polishing the sample surface with a diamond abrasive disc or coarse sandpaper, use a POS/POH abrasive disc with 3 μm polishing fluid for precision grinding. Two polishing steps can be used to achieve a perfect sample surface.

POS/POH grinding wheels replace multiple grinding steps with a single step, typically P320–P2000. They allow for shorter grinding steps while ensuring high-quality results. Their consistently high material removal rate and long service life compared to traditional sandpaper mean no time is wasted changing abrasives, significantly reducing overall sample preparation time. POS/POH grinding wheels are ideal for preparing large batches of samples with high repeatability.

Specification

| POS | medium hardness – <150HV ~ 450HV |

|---|---|

| POH | medium hardness – 150HV ~ >450HV |